What You Should Know about Hardware Development

(The Chinese version of this article is written by Yun-Chieh Hsu and published on MakerPRO)

If you are a startup currently developing a hardware product, then it is necessary for you to learn about the hardware development process. In addition to knowledge from books, it is more crucial to accumulate real life experience. But you may wonder, what is the standardized hardware development process?

Usually, the whole process is called product lifecycle management (PLM), and it encompasses specification, research and development, design, manufacturing, sales, service and maintenance. A standardized PLM can be divided into 7 different phases, and among all the phases, engineers often will be involved in the following three phases: engineering verification test (EVT), design verification test (DVT) and product verification test (PVT.) Want to learn more about what you will encounter in each phase? Here is the detailed introduction:

1. EVT

There are three major steps that need to be taken during the EVT phase: verifying the function of prototypes, generating BOM for budget calculation and pre-scan products to see if they meet the security guidelines.

2. DVT

The main task during DVT is to conduct software quality assurance (SQA) test, pressure and temperature test, bug test and security standard test. The so-called Monkey Test is also part of DVT. Monkey Test generally means testing the limit of hardware and software. If products fail to pass the test, companies will be able to know how to improve the quality of their products accordingly.

3. PVT

Before products enter the PVT phase, they have generally passed most of the design verification tests. The purpose of PVT is to test the manufacturing process before going into mass production. Additionally, companies will have to take the manufacturing number and manufacturing time into consideration. It is intended to enhance the manufacturing quality while reducing the manufacturing time. In other words, this phase has a lot to do with the manufacturing budget.

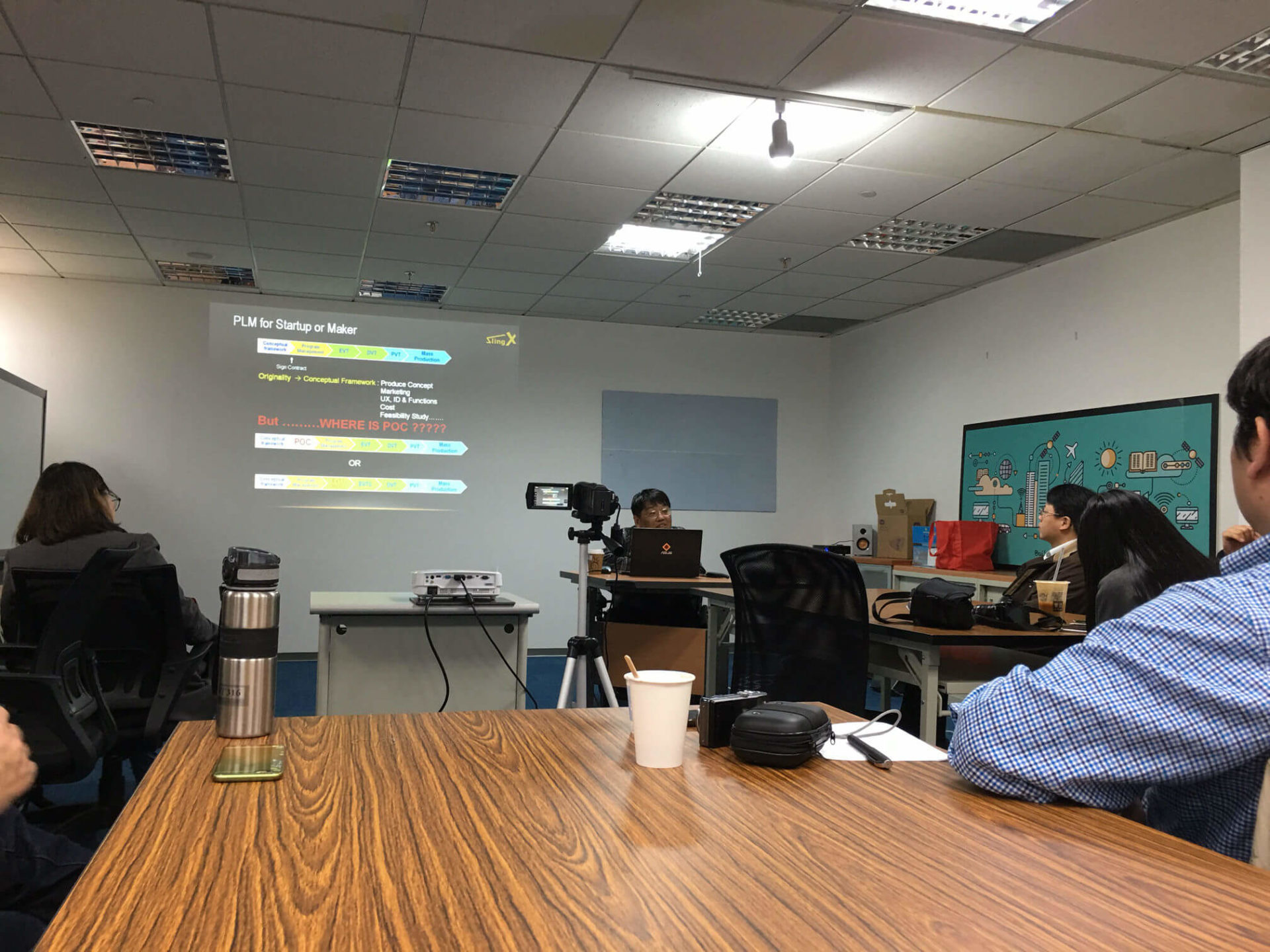

PLM for startups and makers

After learning about the standardized PLM for big corporations, you may wonder if it is the same for startups and makers. In fact, the biggest difference between PLM for startups and the standardized PLM lies in the conceptual framework, which includes:

- Product concept

- Marketing

- UX/ID and functions

- Cost

- Feasibility study

Most of the EMS companies won’t take market sales into consideration at this point, and they generally focus on testing products. It is because most large corporations’ cases already have their own marketing strategies. On the contrary, makers and startups need to focus on maintaining originality and take future development into consideration. As a result, the PLM for makers and startups need to focus more on product concepts, market planning, interface design, and market analysis.

Where should POC be placed in PLM?

For startups or makers, it is crucial to know how to place their POC (proof of concept) stage. POC can be placed before or after program management, and what is the difference? For makers who have solid technical backgrounds, they can place POC before program management because they are able to finish the mechanical design of their products and then let EMS or SI companies help with manufacturing and testing. Placing POC after program management suits makers who only have ideas but lack solid technical backgrounds to produce their prototypes. They need to rely on EMS companies to turn their ideas into actual prototypes.

The biggest difference between hardware and software is that hardware has to put manufacturing requirements into consideration. In other words, companies will have to follow the drills of hardware manufacturing. The steps above are very important to makers who are planning to manufacture small amounts of products. After all, getting familiar with the design process is the best way to smoothly negotiate your needs with EMS companies.