Understanding PCB Materials types

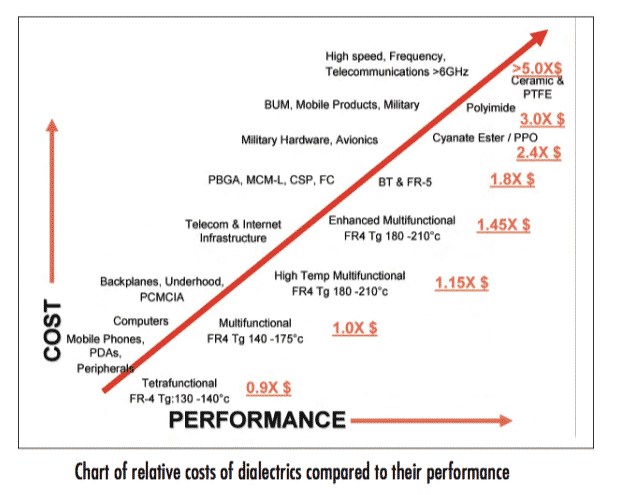

There are several types of PCB material in the market, with many of them being a hybrid of 2 or more materials combined to meet higher performance or to meet special requirement. No matter what material you choose at the end, these are the key factors in determine which material to choose:

• Cost

• Impedance stability

• Signal Loss tolerance

• Dissipation factors

• Thermal conductivities

Most PCB material selection starts with the material’s dielectric constant, which is the energy storing capacity of the material. It’s an important parameter that will be used to target insertion loss for an RF/microwave circuit, a low number is preferred for high frequency application.

Here are some of the common material used for PCB:

1. FR2 (Flame Resistant 2) – Also known as phenolic. Cheap, common in low-end consumer electronics with single-sided boards.

2. FR4 (Flame Resistant 4) – a glass fiber epoxy laminate. It is the most commonly used PCB material. It is cheap yet it has high dielectric strength, high mechanical strength, light weight, resistance to moisture and the versatility for wide arrange of application.

3. MCPCB (metal core) – Most common used in high heat application such as LED light, it uses metal as its core such as aluminum, copper or a mixture of different alloys to maintain high heat dissipation.

4. Polyimide / Pyralux – Used for high heat resistance and often used for flexible printed circuits, common in small form-factor consumer electronics or for flexible interconnects.

5. PTFE – Also known as Teflon, excellent in high RF/microwave PCBs for its low loss and low dielectric constant. It is typically reinforced with fiberglass, ceramic materials to strengthen its mechanical strength.

6. Ceramic – Often found in aerospace for High temperature, pressure, insulation, frequency and high reliable

For further read : PCB Surface Finishing

For further read : PCB Types