EMC and EMI – The Issues You Should Never Skip in Product Development

Designing of any electronic product and in particular the development of an IoT device must all undergo tests to meet safety and compliance guidelines established by testing labs and organizations. These tests focus on electrical compatibility in the environment in which all electronic components must basically share the space accordingly and not interfere or cause harm within the electronic space that all devices operate under.

What all electronic devices do is emit electrical magnetic radiation of some amount and in order to work efficiently and safely, and these electronic devices must not cause interference between each other. If so, the result could be as simple as a device shutting down and not work or to the extreme of causing harmful damage to not only other devices but to the physical environment in which it is placed.

This usually results in an issue of thermal problems that could result in becoming a fire hazard. So the 2 terms you need to get familiar with are EMC (Electromagnetic Compatibility) and EMI (Electromagnetic Interference).

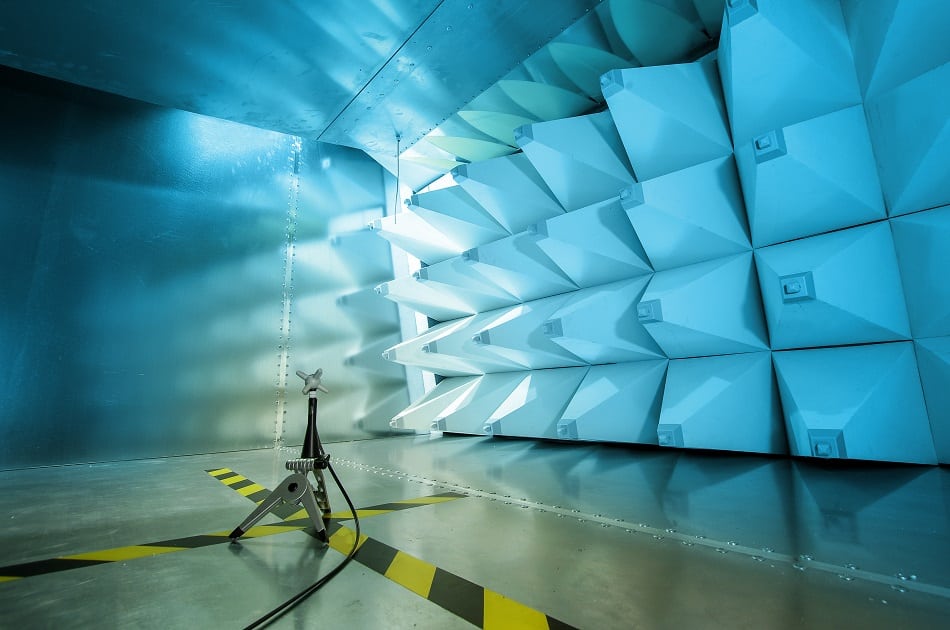

EMC/EMI testing exists to ensure that your electrical device doesn’t emit a large amount of electromagnetic interference (known as radiated and conducted emissions) and that your device continues to function as intended in the presence of several electromagnetic devices safely and without any harm to the environment. Most importantly, your device does not provide any harmful emissions that could be deemed dangerous or hazardous to humans.

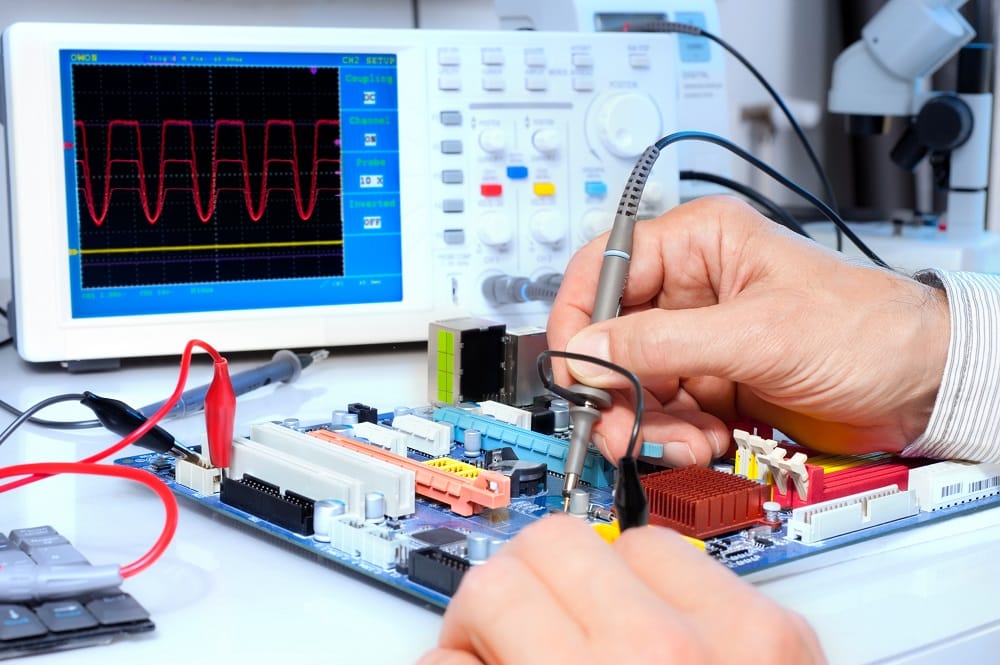

Product Development – EMC/EMI tests

In the product development phases of EVT/DVT/PVT and finalizing to MP, before you can go onto PVT, you must go through the various EMC/EMI testing to check on the viability of your product. There are 2 major organizations in North America that are NRTL (National Recognized Testing Laboratories) recognized by OSHA (Occupational Safety and Health Administration). These two organizations are known as UL (Underwriter Laboratories) and ETL (Electrical Testing Laboratories) owned by ITL (Intertek Testing Laboratories). These 2 organizations do the necessary testing to make sure electronic devices and components meet the proper safety requirements. EMC and EMI testing are part of their rigorous tests to ensure that the devices tested do not emit harmful radiation and cause interference that usually results in thermal issues that lead to shutdown, harmful emissions to both the environment to physical human exposure.

EMC Power Focus

In power supplies, the idea of regulating the temperature of the overall components on the device itself is a matter of controlling the EMC and what effects it has internally to the device. Power supplies are subject to thermal inefficiencies when the amount of power provided to the internal circuitry starts to emit harmful emissions magnetic or otherwise which then causes a heavier load on the power supply by means of power consumption. This usually results in heat build-up that if not taken care could cause both the power supply itself failing and what could be worse is “frying” the PCBA board. Often times electronic devices have grounding loop errors and the need to provide proper heat dissipation in form of heat sink and/or even a cooling fan. These results show that when EMI causes things to become less efficient, everything else component wise starts to get effected and results could result in a failed device. The testing for such system vulnerability needs to be considered in order to sale devices onto the market. This is why ultimately safety is the real important thing to understand about complying with the EMC/EMI testing.

UL and/or ETL will ensure that your product meets all the EMC/EMI compatibility testing along with ensuring the product gets a UL/ETL stamp or certification.

EMC and EMI Testing Comes Together

The common issues in electronic designs that you must face is the fact that if there are EMC/EMI issues you essentially will have thermal issues and with over powerful electronic emissions. Those emissions will cause interference with other devices. In every step of the product development, you must face the challenge to design and develop step by step. In product development, there is a stage in which your project must pass certain tests in order to be deemed safe and move to final design for production

What test you should plan on for your particular product is often at first daunting to a designer because many people will tell you there are various tests that must be gone through in order to certify your electronic device. As mentioned above the real things to focus upon is any issue with thermal and issues of electronic emissions that are within the guidelines allowed for your electronic device. There are organizations setup to monitor and test for these issues and with that comes the ability to pass such tests to allow you to sale your device.

Professional Project Managers Guide You Through Hardware Development Process

TechDesign provides professional consultancy to help you realize your electronic products and achieve success from start to finish. TechDesign helps you to find the suitable suppliers and to guide you through these necessary steps to ensure your project is reliable, safe and meets expectation of the consumer. Now visit TechDesign eService to find the information and resources to start your projects.