Design for Manufacturing – the Process All Hardware Startups Should not Overlook

Design for Manufacturing (DFM) refers to the process of reworking a design in order to make it better conform to the standards required in actual manufacturing. In the DFM process, the focus of hardware startups is to both reduce the complexities involved in mass production operation while at the same time reducing the overall cost of part production. Basically, DFM ensures that your product can be manufactured on time and on budget. Many hardware startups overlook DFM and live to pay the price.

The key aims of DFM are to:

● Reduce costs related to materials and labor.

● Reduce the time taken for the product development cycle.

● Emphasis on standards in order to reduce costs.

In this article, the TechDesign team tells you why you had better not overlook or skip DFM.

Never Skip or Fail to Spend Enough Time on DFM

Many startups mistakenly think that they can quickly design a product just so that they can have their design intent fully realized through a working prototype. They falsely believe that they can just make a few tweaks in order to be ready for production at a later date. A surprising number of companies try to skip DFM or rather skip validation of DFM. They don’t build a product to test it from an engineering and design validation standpoint in order to push the schedule. They go straight to production and find problems when it is way too late.

In this excellent article on Medium, PCH’s sustainability chief Alan Cuddihy states that DFM and validation were the biggest failure point in startup’s product cycle. He explains “it’s the difference between building one of something and building 5000”. Companies often try to go production on designs that they have fully validated or verified and then out that their design was not viable in terms of manufacturing. The source of these issues is that there is a level of naivety and a lack of knowledge about what actually works from a manufacturing process in the early stages of the production cycle. These teams later on find out that what they had planned is difficult or maybe even impossible to manufacture.

The Case of Kreyos

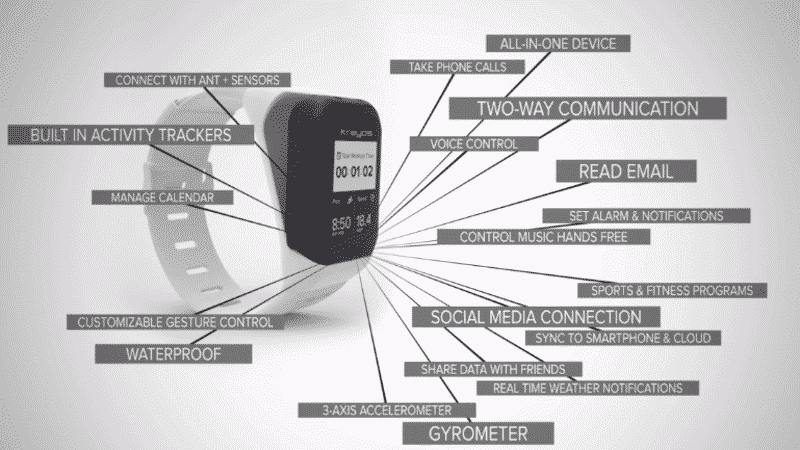

Take for example the notorious case of the Kreyos Meteor Smart Watch. The team behind the Kreyos smartwatch raised $1.5 million dollars through a 2013 indiegogo campaign. On the campaign page they claimed that not only did they have a working prototype, but they had also begun tooling. The company promised early backers that they would receive their watches in November of 2013, just 3 months after their campaign begun.

Over a year later, some backers finally begun to receive their watches to absolutely shocking reviews. In fact, two backers were so incensed, that they penned an internet manifesto that listed everything that was wrong with the Kreyos. Critical issues mentioned by the duo included “unusable speakers and failed waterproofing, on top of poor, buggy firmware and unusable (and even entirely missing, in the case of Windows Phone 8) companion smartphone apps.” Even more shockingly, a user reported that “the watch fails to keep time unless it maintains its Bluetooth connection to the smartphone.” Needless to say the project was a mess and is widely regarding as the exemplar of everything that is wrong with crowdfunding.

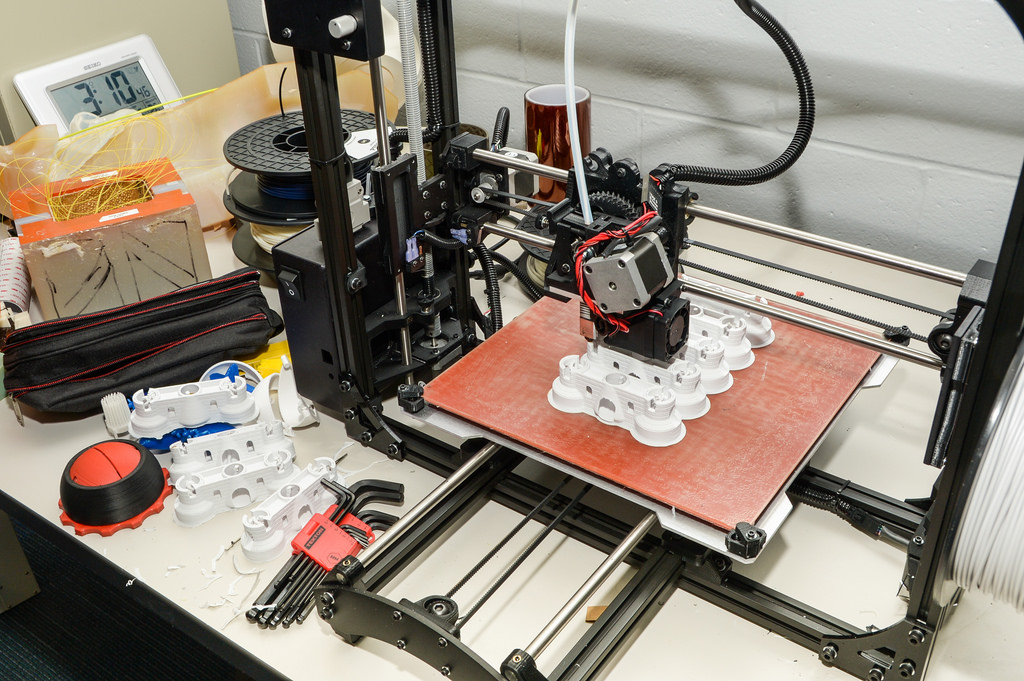

But what actually went wrong? Well the team behind the Kreyos had four marketers and not a single team member with an engineering background. They asked their manufacturer in China to do the design for them. It is a critical mistake to ask your supplier to be your product development partner. You do not solve problems in China, but rather through 3D printing, testing and validation. Don’t count on a manufacturer to solve your design problems and do not expect them to care about details. You need to hire a design engineer who will take into account manufacturing, size of components and how to avoid stuff and choosing the component and make sure your design is ready for mass production.

When to Start DFM?

Elaine Chen of ConceptSpring advises startups to incorporate DFM thinking into the engineering from the very first prototype. If you have a target for your final COGS due to business constraints, you need to be considering this from the being. She says “the best DFM strategy is to design every custom part with the target manufacturing technique in mind. Then, start interviewing suppliers for each part, and engage top candidates in design reviews early and often”. Involving suppliers from the beginning ensures that the parts which are designed are compatible with the manufacturing process and the capabilities of the manufacturing partner.

DFM (Design for Manufacturability) is the key to a good design. Jerry Yang of Hardware Club warns startups away from not learning the manufacturing process early on. He states that by not embracing DFM in the design phases, “hardware startups will repeatedly commit DFM mistakes during the design phase which would at best cause delay in the projects and at worst lead to a back-to-the-drawing-board.”

Stages of the DFM Process

In this article, hardware startup Senic, outlines the stages of the DFM process. This is a good guideline for members of the TechDesign community who are researching the DFM process.

1) Define functions of your prototype: From the prototyping phase you know what you want your product to do, but now you need to lock in the functions.

2) Transition of Tools: At the prototyping stage of your development process, the goal was to work through workable iterations of your device. Now tools like Arduino, Raspberry Pi and 3D printing are not applicable. In terms of electronics, you need custom built circuit boards that can be mass manufactured. For mechanics, you need to use CAD tools that are able to transmit their data to machines and transcribe to 2D drawings with the related tolerances for your manufacturing partner.

3) Set requirements: You now have to set the technical requirements of your device, including:

● Voltage

● Accuracy of your sensors

● Energy usage

● Price (based on your target retail price you need to hit certain price for your materials)

● Dimensions

● Availability

● Shipping Time

4) Research Technologies, Suppliers, Manufacturers: Once you have set your requirements and functions you need to narrow down your solutions. These can be divided by the following

● Technologies: Find what technology is available and what is most suitable for your project.

● Manufacturers: As we have consistently mentioned on the TechDesign blog, your relationship with your manufacturer is make or break for your hardware startup project. This is where TechDesign comes in; we can match you with the right manufacturers. We have a base of verified manufacturers and design houses and are able to match the correct partner with your project, without you having to fly across the world.

● Supplies: Find who will supply the components for your device. Again, this is where TechDesign can be of service. Check out TechDesign E-market, where you can take advantage of our relationships with verified suppliers / original equipment manufacturers in order to buy components directly without the need for a distributor.

5) Try Out Samples and Decide for Technology

Data sheets are fine, but you won’t know what really works until you try it.

6) Dig Deep into Specific Parts, Suppliers and Manufacturers

Try and contact as many companies as possible for your search. Alternatively, reach out to us at TechDesign and we can do the hard work for you.

7) Choose your Components, Suppliers, and Manufacturers

After narrowing down your list of potential suppliers, it’s time to make decisions.

8) Pre-series

Now you are ready for your first batch of devices. The purpose here is to get an idea of what the supply chain looks like and understand who this means in terms of manufacturing.

If you are working on a project and want to partner with a supplier in order to hone your DFM process, then please reach out to use at TechDesign. Simply, submit your request (RFQ), and you will receive competitive quotations from top electronics manufacturers. Choose the one that best fits your project-scope and budget and kickstart the process of having your brilliant idea manufactured in an instant. What’s more, TechDesign offers NDA and Escrow payment protection, meaning you don’t have to worry about having your money or ideas stolen.

Get a free quote for your project today.

Sign up to become TechDesign member and get the first-hand supply chain news.

The way of your explanation is good. Very informative blog. Waiting for your next article with such unique information.

Thanks for the feedback, we will keep it up!